The safety vest is one of the most popular pieces of high-visibility clothing that is not only used by construction workers, but also the public. High-visibility color has also branched out into everyday clothing items, as well as advertising and packaging. However, how high visibility came to be is quite possibly the most unexpected reason. Tomorrow, August 20th, marks the 25th anniversary of Bob Switzer’s passing, the man behind fluorescent colors and clothing.

In the 1930’s, Bob was working for the Heinz Ketchup manufacturing factory in Berkley, California. During a shift, he unfortunately tripped over boxes causing him to fall and hit his head so hard that it fractured his skull, severed the optic nerve in one of his eyes, and put him into a coma. When he awoke, the doctor informed him that his dreams of becoming a doctor were no longer possible due to his injuries, and he had to remain in a dark room until he was fully recovered. Keeping him company was his brother, Joe, who was a magician. While they sat in the dark, Joe was trying to brainstorm ideas to make his shows more visual. He was experimenting with fluorescent chemicals that caused things to ‘glow’, and inspired Bob. Once Bob fully recovered, he started experimenting with his brothers fluorescent mixes by adding them to wood varnish. This combination made a bright paint that grew even brighter under black light, which he then used on his wife’s wedding dress, making it the first piece of high-visibility clothing ever!

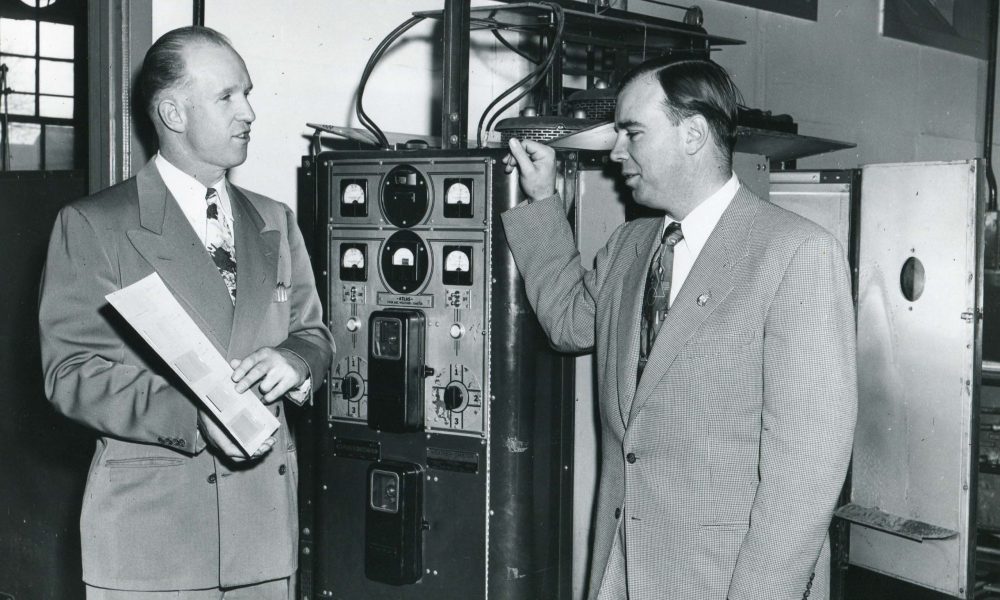

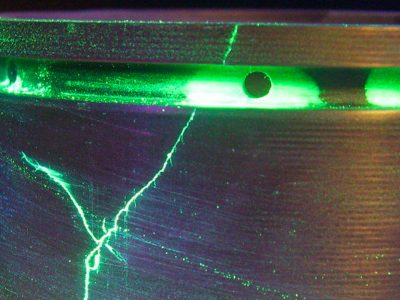

In 1934, they established Fluor-S-Art Co. to further develop and sell these black light paints, and eventually partnered with Continental Lithograph in Cleveland, Ohio. The brothers moved the company from California to Cleveland, and development picked up quickly. Over the next two years, they developed two flaw-detection fluorescent dyes, Zyglo and Magnaglo. They were used to find defects in machine parts and were a huge success. Due to the positive reactions, this caused major stress between the brothers and Continental Lithograph over its rights, leading to their separation and the brothers creating their own company in 1946 called ‘Switzer Brothers Inc’. As time passed, new colors were created that were even brighter than before, which are known today as the DayGlo colors. War was a large part in the use of these colors as aircrafts and pilots were marked with DayGlo orange; buoys were also coated with high-visibility paint to indicate areas that had been searched and cleared, and the Navy used fluorescent markings to land aircrafts at night which proved to be a huge advantage. Eventually, the high visibility faded away after the use of camouflage became highly popular, but that didn’t stop its popularity.

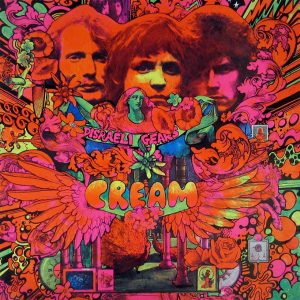

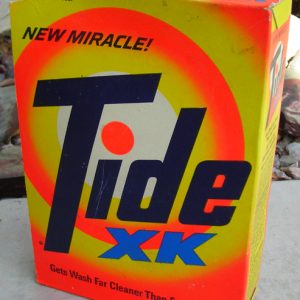

The construction industry started having huge impact on the use of high-visibility clothing, but it didn’t start in the United States. In Scotland, the railroad workers began using high-visibility garments in 1964 when Scottish Rail became the first company to mandate workers to wear the clothing for safety precautions. The growing fashion trends also aided in its popularity and normalcy, as well as in art. The album artwork for Cream’s 1967 album Disraeli Gears is all DayGlo colors and can be seen in many other psychedelic visuals. Tide Detergent also adopted the DayGlo colors for their orange packaging! The brothers began noticing the growing popularity in their newfound color wheel and changed their company name to DayGlo Color Corp in 1969, which is still the name today. Eventually, the U.S. caught on and the requirement for high-visibility clothing in high-risk work environments was set in place with the 1974 Health and Safety Act and again in the 1992 Personal Protective Equipment at Work Regulations. Now, there are three classes of safety vests set in place by the American National Standards Institute. The different vest classes differ on the amount of fabric used, style of the vest, and what occupation would wear them. However, all vests are required to have two fabrics – reflective fabric and retro-reflective fabric. The reflective fabric is the background mesh that uses DayGlo colors. This fabric is made to be highly reflective against the sun making it very bright and can be yellow-green or orange-red. The retro-reflective fabric are the silver/gray stripes that are not only reflective to the sun, but any direct light source like headlights or flashlights.

Class 1 is a very basic vest that has the least amount of fabric. Personnel wearing these vests are in low-risk areas where if traffic is present, the speed limit doesn’t exceed 25mph (parking attendants, delivery drivers, etc.). Class 2 vests have more fabric to connect the front and back panels together, as well as more striping. Personnel wearing class 2 vests are near roadways with traffic exceeding 25mph, such as surveyors, and are helpful in more severe weather. Class 3 has the most fabric across the board as it is a t-shirt sleeved vest. This vest is worn by workers with higher risk environments such as construction, utility, and emergency service workers. Those working on roadways of 50mph or higher also should be wearing these vests. You may notice that the class 3 vests are more used than the other two, which is why companies have begun making regular t-shirts that are designed like the class 3 vest. This allows workers to ease up on layering their clothing which could cause bodily harm depending on the location, as well as other dangers of having a loose piece of clothing around your main torso.

Safety vests are also popular among people just enjoying daily activities. Many bikers and runners wear safety vests on roadways to be more visible to those driving. Motorcyclists also wear safety vests as they can be the deciding factor between life and death. A study in 1981 found that two out of three motorcyclists were killed in car accidents due to the car driver not seeing the motorcyclist. With safety vests, visibility is increased exponentially, especially in areas with lots of movement and people. The safety vest has also made its way into designer fashion where Balenciaga tried selling a safety jacket for $5,625! DayGlo colors have become extremely popular in fashion and there doesn’t seem to be a day that they’ll ever go out of style. Who would have thought that a wedding dress covered in bright colored wood varnish would be the cause of saving so many lives for generations and advertising to the public. If you enjoyed this blog, please leave a comment below or share with your friends and family via the icons!

Share this Post