Construction workers rely on many things to maintain safety. Clear communication, awareness of their surroundings, and their clothing choices all play a part in their personal safety. Bright shirts allow workers to be easily visible in high traffic job sites, but also wearing a hard hat allows keeps them safe from unexpected events. Hard hats have been around for centuries and continue to be one of the most influential, and underappreciated, safety tools used in the industry today!

One of the first ‘hard-hats’ ever discovered was from the 13th century! Archaeologists determined the helmet was from the Bronze Age and was referred to as a ‘Boar Tusk’ helmet. These helmets were made from a leather cap that was padded with felt on the inside, with slivers of ivory from the tusks of boars attached on the outside. To make these helmets, it is said to have required killing 40 to 50 boars for their tusks. These helmets are also mentioned in the famous Greek epic poem by Homer, The Iliad, which was written 800 years after these helmets were most popular! Although the helmets were not strong enough to protect from weapons and brawls, they were used heavily as status symbols for leaders and family heirlooms. Throughout history, helmets were used for status identification in war until metals and steel became popular. Head protection began to evolve to provide better support for those fighting, which proved successful.

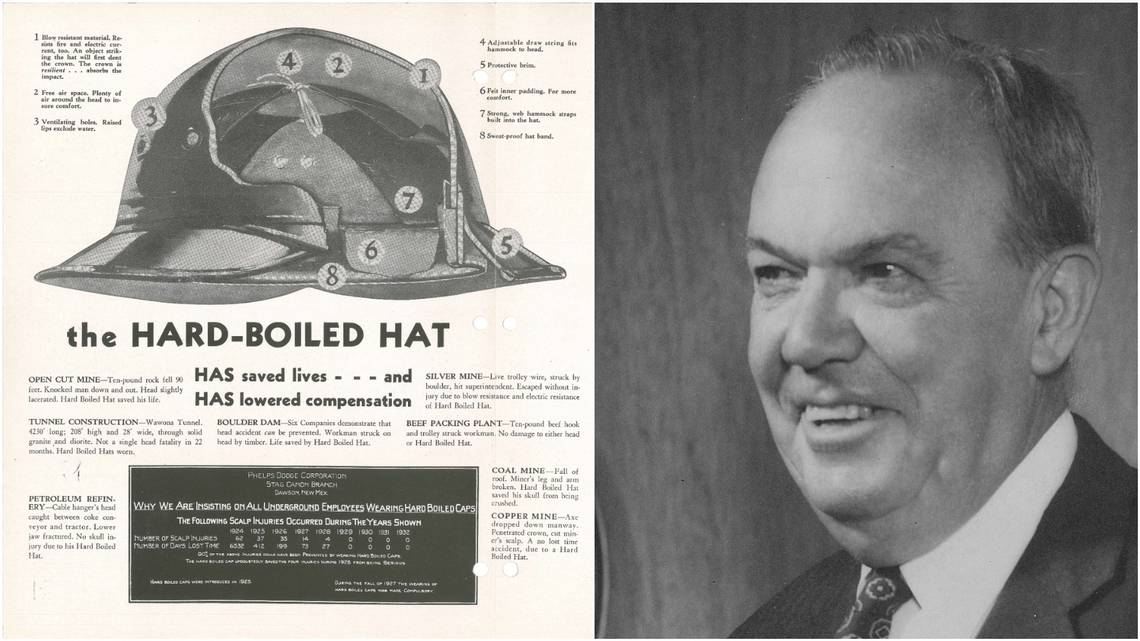

World War 1 is the fifth deadliest war in the world, having killed an estimated 18 million people, 7 million of those being civilians. However, many more could have died had the steel helmet not been created. The ‘Doughboy’ hat was worn by many soldiers from all over the world, recognized as different names depending on the soldiers region. The steel hat was heavy but provided immense protection from threats, securing under the chin with a leather strap. At the time, Lieutenant Edward W. Bullard was serving in the war for America. When he returned home, he rejoined his fathers business at the mines where they manufactured carbide lamps and other equipment. It was at this time he began making comparisons between the protective gear between the mines and war. In 1919, he began development for a hat like the Doughboy for miners to wear. After different prototypes, he had developed the first design of a true trades ‘hard-hat’. He called it the ‘Hard Boiled Hat’ as the canvas and leather used was steamed to fit the miners head perfectly, similar to boiling an egg. It was then coated in shellac to become hard and sturdy. The design of the hat also made it more available due to costs. The doughboy hat was not ideal for mining as it was very bulky, but due to being steel it cost way more than many could afford.

With the new creation of the safety hat for miners, Bullard began making more catered to specific trades, as well as perfecting the miners hat. He created a protective cap for U.S. Navy workers in shipyards and added a holder for a carbide lamp for miners. He also created a hat made from Bakelite, an early form of plastic, that helped withstand heavy-duty wear in more physical labor occupations. As time continued, construction history was being made. The Hoover Dam was started in 1931, with the Golden Gate Bridge following in 1933. The dam was the first major construction project in the United States to require workers to wear protective headgear due to the immense number of materials, scaffolding, and other dangers present. In photos, you will see many different variations of Bullard’s hats, as well as some wearing Doughboys! The Golden Gate Bridge followed suit, and protective headgear is now a requirement all over American construction sites. With hats becoming a requirement, Bullard continued to reinvent the hat improving it each time. In 1938, the first aluminum hard hat was manufactured. Although it was durable and lightweight for workers, aluminum is a conductor for electricity. With this major setback, a fiberglass heat resistant hat was created; Unfortunately, this material was costly, thus the hard hat material was then replaced with thermoplastics. Since then, hard hats have been made using plastics as it’s cost effective, lightweight, and durable for long time periods. Come 1982, Bullard incorporated the strap that is present on all hats. The back strap has a non-slip ratchet suspension equipped with a knob that allows workers to customize their hard hat to fit their head as needed. This hat is the 3000R hard hat, which has become the basic standard for hard hats everywhere. The hard hat continues to be improved for safety, especially with Bullard Co. continuing to be a leader in construction safety equipment to this day! Being struck on job sites is one of the top reasons for injuries, with 65,000 cases in 2012 involving head injuries. Unfortunately, 1,020 workers died from head injuries that same year, and 84% of workers involved across the incidents were not wearing hard hats. Traumatic Brain Injuries (TBI’s) are the primary type of injury in construction, which can ultimately cost the injured person and the company a lot of money. For a mild case, finances can total up to $100,000 with severe incidents leading up to $3 million or more.

Hard hats can also pose as status symbols like those in the Bronze Age. If you ever look at different sites, you may see a large variety of colors. Different colors help workers identify each other without having to ask around for the correct person. Some colors are also available simply for visibility purposes.

White hard hats are mainly used by Supervisors, Foremen, and Engineers.

Brown hard hats are worn by workers who are handling heat, such as welders.

Green hard hats are used mainly by workers who are conducting safety inspections, or sometimes new hires on site.

Yellow hard hats are used by workers who are handling earth moving or general workers on site.

Blue hard hats are used mainly by carpenters, technical workers, and temporary help.

Orange hats are used by many road workers, and the occasional visitors on site.

Grey hard hats are primarily used for visitors on site as they are kept mainly out of high hazard areas.

Pink hard hats are mainly for high visibility purposes of workers.

As the hard hat continues to reach new standards for safety, it also continues to receive the deserved recognition. In May 2020, Bullard was inducted into the National Inventors Hall of Fame, where his efforts in creating new safety standards and tools for the trades will be recognized for the rest of time. The hard hat saves lives every day, all across the world, and its use goes unnoticed by many who rely on it unknowingly. If you liked this blog, please share it with your friends and family via the icons below or leave us a comment!

Share this Post