If you keep up with current events, you may have heard about the recent tragedy that struck in Berlin, Germany. Located in the Radisson Blu Hotel was the Guinness World Record holder for the Largest Cylindrical Aquarium called the AquaDom. Standing at 50-feet high and 38-feet in diameter, the AquaDom was home to around 1,500 fish and held 1-million liters of water. Unfortunately, on December 16th, it suddenly burst causing a tidal wave in the lobby that burst through the front windows and flooded the street and neighboring businesses. Fortunately, the tragedy struck very early in the morning; however, a hotel employee and guest were injured and almost all the fish were killed. The burst was so powerful that local seismographs detected the incident!

Three weeks later, the public is still left wondering how the incident even occurred in the first place. As of now, there is no speculation of foul play luckily, but ‘material fatigue’ is just as frightening. The AquaDom was constructed in 2003 with 41 acrylic panels. 26 were used for the outer cylinder, and 15 for the inside that contain the elevator, with the cylinders being bonded together on-site during construction. The cylinder sat on a concrete base measured at 30-feet high, making the total aquarium height around 80-feet. At the bottom of the aquarium, the acrylic panels were 8.7-inches thick and tapered to 7.1-inches at the top. Having recently gone under renovation to fix seals and repair small acrylic repairs in 2020, it’s hard to believe the aquarium ruptured due to material fatigue as it should have either been caught during the recent look over, but also could have occurred very recently. It’s been speculated that due to freezing temperatures in Berlin, the acrylic may have cracked increasing the water pressure thus resulting ins disaster. Although this entire situation is devastating, it could have been much worse had the aquarium used glass instead of acrylic panels. Within construction, it’s very easy to assume that most transparent materials for windows, doors, and other pieces use glass. However, as technology has evolved so have building materials. Glass has been around since 1500 BC, yet it was largely used for decorative pieces and jewelry. Window glass wasn’t in demand until the early 1800’s, with heavy machinery not invented for another 100 years. The invention of acrylic glass came shortly after regular glass started being mass produced. World War 2 was a big time for acrylic demands as the glass was shatterproof, leading to windshields, aircraft windows, and gun turrets being made with acrylic. After the war, acrylic grew more popular in every possible industry – police riot gear, hard eye contacts, hockey rink barriers, and zoo enclosures. Acrylic glass is also widely known as Plexiglass, due to the popular brand name association.

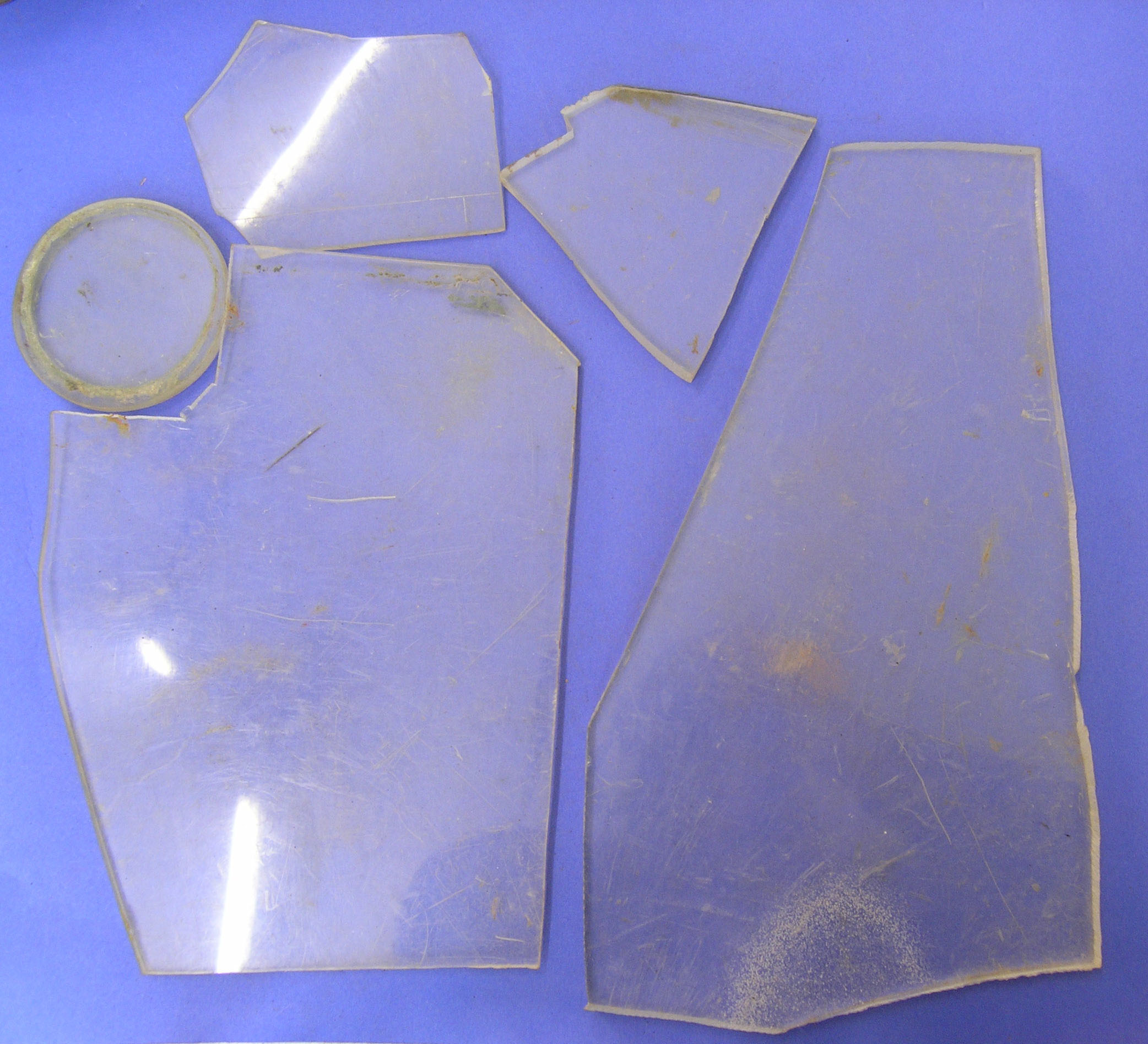

There are many amazing traits of acrylic that make it such a comparable material to regular glass. Acrylic is 17 times stronger than normal glass making it shatter resistant, although, everything has a breaking point. Shatter resistant just implies that should an acrylic sheet break, it will not be broken into many tiny pieces. Noticed at the AquaDom, you can see the giant shards of acrylic laying throughout the lobby. Acrylic also weighs half of what glass does, which is beneficial for many tasks such as clean up, installation, and transportation. Acrylic glass is also a very malleable material. With glass, special pieces must be manufactured to the specifications needed, whereas acrylic can be bent and molded into the necessary ways needed to fit a space. Acrylic sheets can be warmed and melted to create bends, and they can be placed in areas where glass can’t. Many skylights in either residential or commercial spaces are made of acrylic due to weather-related purposes, cleaning, and the general force of gravity.

While acrylic has many pros, that means it has cons. Although acrylic is extremely durable when under extreme pressure or force, it isn’t scratch-resistant. Acrylic also has potential to fade from sun exposure and turn yellow. While many manufacturers pride themselves on high quality material and will replace the acrylic due to yellowing, it’s not a fun task to have to replace material due to something unavoidable, like the sun. Acrylic is also not easily recyclable. While glass can be endlessly recycled into new products of equal quality, acrylic cannot. Due to not being an eco-friendly material, breaking it down like glass could cause harm from emission of dangerous chemicals. Acrylic also cannot be recycled and made into products of equal quality, so they can only be downcycled. Often, acrylic glass is broken into small pieces and used that way or end up in a landfill entirely. However, the construction and manufacturing industry are making strides on finding ways to make acrylic glass more recyclable, like TAP Plastics and their EcoGreen Recycled Acrylic.

Now, the comparisons don’t stop there as another material that compares to both acrylic and glass is used – polycarbonate. Polycarbonate is 250 times stronger than glass and deemed ‘unbreakable’ at certain sizes. It is also considered a plastic rather than a glass due to its thermoplastic production process. With being a thermoplastic, polycarbonate can easily be recycled by heating the plastic into new shapes or products, while maintaining the quality. However, like acrylic, it is shatter-resistant (or shatter-proof in certain cases) but easily scratched. It also has a chance of yellowing faster than acrylic due to its lower UV tolerance.

Between these materials, there are many similarities yet differences that play a big part in construction of a project. Choosing the best option can be beneficial to not only the client, but also the environment!

Glass Applications

Store Fronts

Without distortion and complete clarity, items can be seen easily and clearly.

Room Partitions

Areas that are unlikely to experience force sometimes use glass to give a luxurious feel.

Furniture

Coffee tables, pulpits, many pieces use glass, even stair railings!

Acrylic Applications

Sporting Arenas

Hockey rinks often use acrylic for the barrier around the rink as it’s light, clear, and affordable.

Aquariums

The sheets can be bent, and the glare is also very minimal compared to glass.

Screen Protectors

If you have a screen protector on any of your devices, chances are you have been looking through acrylic!

Polycarbonate Applications

Greenhouses

Polycarbonate traps heat better than glass by 60%.

Eye Glasses

Eye glass lenses are often made from polycarbonate to avoid breaks where the human body could be harmed.

Windshields

Off-roading vehicles can experience such heavy force that vehicles with a strong windshield are highly sought after.

Share this Post