If you’ve ever lived in an apartment complex, at some point you may have complained about how loud the neighbors are. From hearing their phone conversations to them walking back and forth, the way a building is constructed and insulated plays a large part in how audibly comfortable the residents, or staff in an office building, are long after the project is over. Understanding the initial problem helps contractors decide if they will be dealing with soundproofing, sound absorption, or both, which ultimately affects the materials that will be needed and any budget adjustments. Understanding how sound travels through different materials, and how it affects other areas of a project is key to great outcomes.

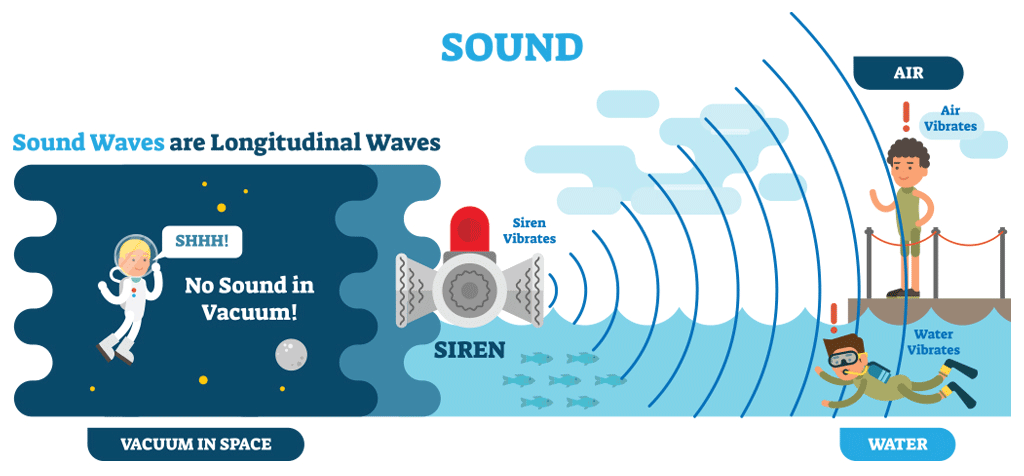

The first step in sound construction is understanding how sound travels and interacts with materials. Sound is a form of energy that travels in all directions from its source. For the sound to travel, it needs a propagation such as a gas, liquid, or a solid for the waves to travel through molecules. This is why hearing sound is impossible in outer space! Due to the need of molecules, the difference in molecule size and spacing affects how the sound travels. For gases, the molecules are spread far from each other making the sound wave take longer to travel, thus hearing the noise later (ex: watching lightning strike and hearing thunder moments after). Compared to a liquid where the molecules are closer together, you would hear the same sound sooner in water than in air, and the same for solids having the densest molecule makeup of the three making sound travel the fastest.

Since we live in a physics-abiding world, the concept of elastic properties starts to play in on what solid material to choose as all construction materials are solid. The elastic properties help determine how fast sound travels through a solid and how the material maintains its shape when put under force. Density of materials also plays into understanding the elastic properties too since solids have different masses per volume. For example, rubber versus steel. Rubber is a solid with large particles in its makeup. Steel is also a solid, but the particles are much smaller than rubber, which can be felt by the weight difference of the two. So, if you were to knock on them both, the sound would last longer and travel faster through the steel than the rubber. This is because although the rubber and steel are both solids, the particle differences cause the sound in rubber to travel slower (60 m/s) than the sound through steel (6,000 m/s). Now that we have a basic understanding of sound travel, contractors must understand what issue is present. Do we want to absorb sound, or do we want to prevent sound? Many outside of the industry use the terms soundproofing and sound absorbing interchangeably, when really, they’re usage depends on what your goal is. If you want to address how a busy road affects the noise of your home office, sound proofing is needed. However, if your living room has extreme echoes, you will want to address the rooms sound absorption. Sound absorption is easier to address as adding more furniture or installing carpet helps lessen the echo as the waves have more areas to sink into that won’t reflect the noise back like the walls. However, sound proofing is more complex at times as builders are dealing with different sound transmissions.

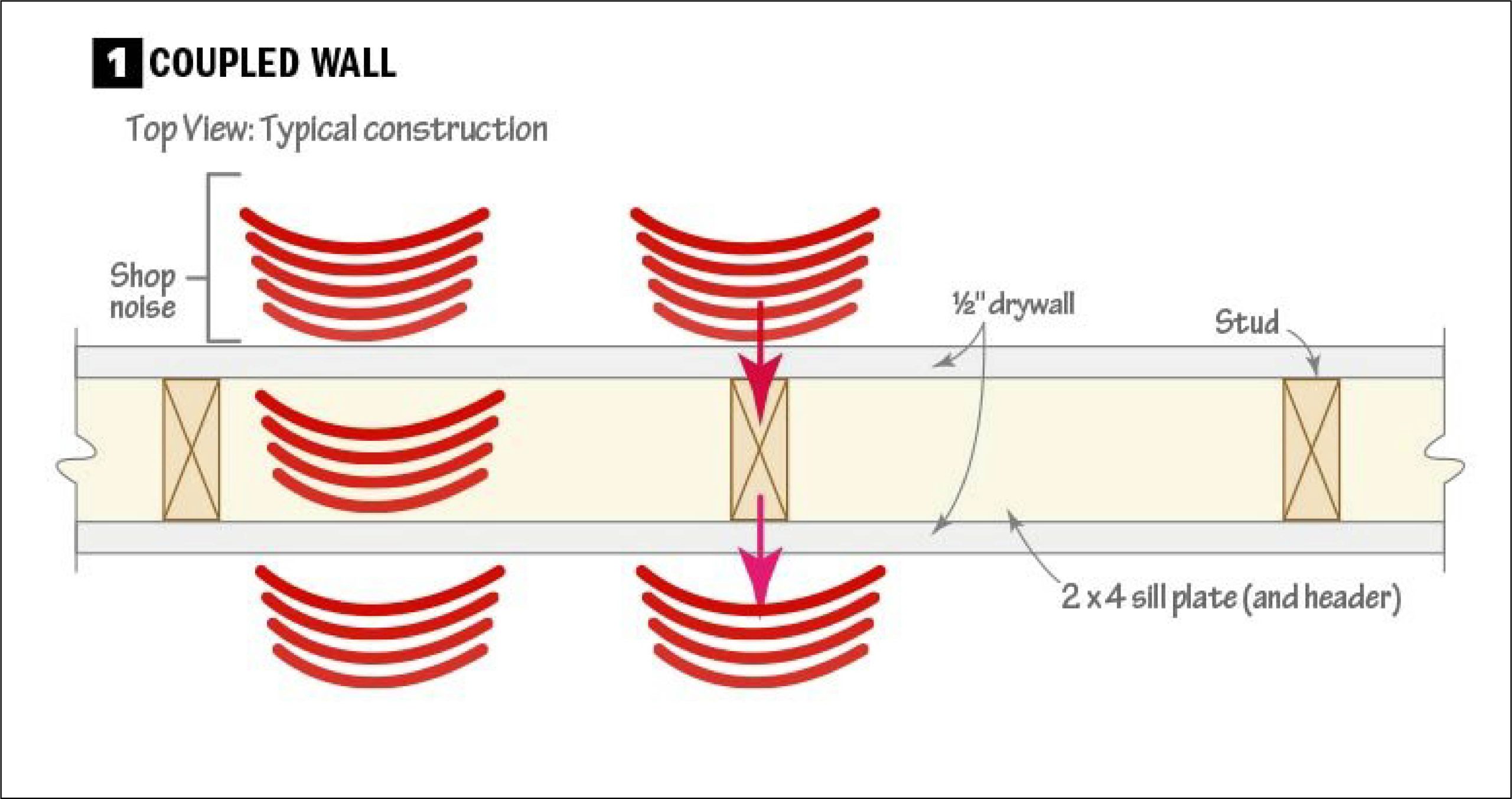

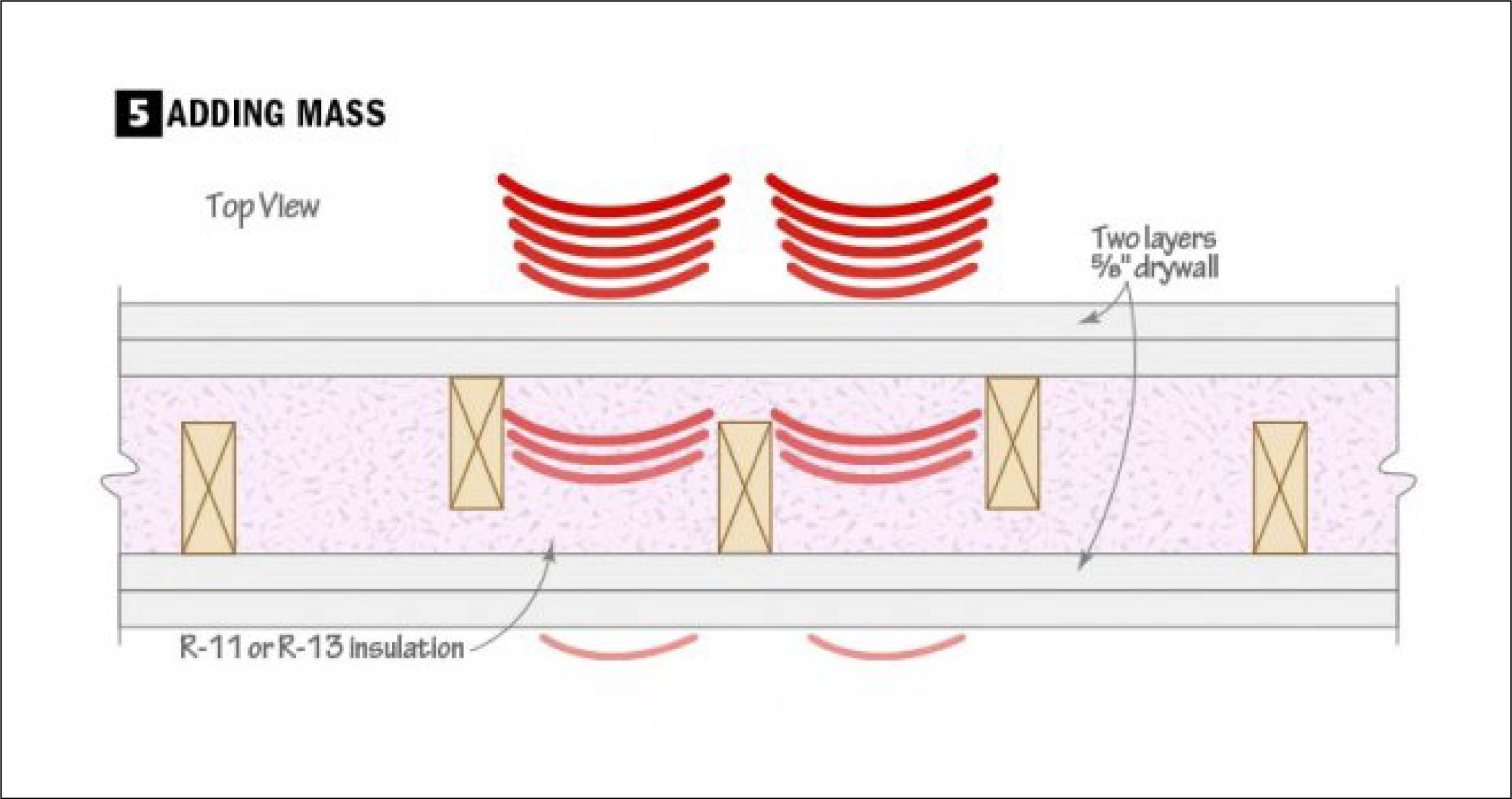

For instance, floor-ceiling joists in apartments or office buildings create a sound transmission called impact-sound transmission, such when someone would walk or roll a chair across their floor and you hear it in the ceiling below. There is also airborne-sound transmission, or when sound for outside passes through walls into your home or business. In many projects, contractors will use the method of decoupling as it can be used on every face of a room. Decoupling is when builders will create a wall, for example, and instead of having 2 panels of drywall over another to create a thicker wall, they will space them apart and sometimes place insulation between them. This allows sound to travel through the first solid layer, which then meets either open space or an insulated space. This helps slow down the sound waves, or dampen them, before reaching the other solid side, thus allowing the sound to lessen before reaching the ears of others.

For ceilings, the drywall is suspended by wires, and often have fiberglass insulation to further block impact sound from above. For flooring, lightweight concrete flooring can give the same effect of decoupling but will reduce airborne sound rather than impact sound. Depending on the owners budget, decoupling may not be affordable. In this case, the difference in wall finish and insulation can help make sound proofing still possible. Mineral-fiber insulation is denser than the standard insulation used, as well as having a higher burning point and lower moisture absorption rate. Limp Mass Sheets are also helpful in dampening sound along with being flame retardant and easy to install.

Some prime examples of rooms with sound proofing and sound absorption are recording studios. When creating music, artists and musicians need as little to no echo as possible to create authentic recordings for their music. It’s also become a popular feature in large companies to have single quiet rooms for people to use for working quietly, or a place where they can decompress from a stressful morning. There are also rooms that take sound absorption and proofing to an extreme. In 2015, Microsoft constructed the World’s Quietest Room known as Building 87. These rooms are known as anechoic chambers as they have negative decibels, which is the measurement for sound. While a normal conversation averages at 60 decibels (dB), space where sound isn’t possible would register at zero. However, Microsoft’s anechoic chamber registers at -20.35dB! If you’re interested in this phenomenon, click here to check out the math behind why this is possible!

The chamber is constructed inside the main building but sits on its own foundation of springs to remove the possibility of any sound coming from elsewhere through the floor. The walls, floor, and ceiling are covered with large fiberglass wedges that absorb all sound creating an environment where all sound is absorbed internally. There is no true floor, as only a taught wire screen is available to walk across to all sound to escape downwards. For sound proofing, B87’s ‘framework’ is six layers of concrete and steel that destroy any noise trying to come through the walls. It is said that sitting inside the room long enough will allow you to hear your own blood running! While this may seem extreme, it has a lot of purpose for Microsoft. Inside the anechoic chamber, they test the clicks and hums of keyboards, mice, and other technology to create world-winning products that are comfortable for the user in all aspects.

While most people are not testing computer clicks on a regular basis, having a quiet environment to work and live is highly important to many. Ensuring that you communicate that importance to your contractor will not only help avoid changed plans late in the game, but it can also prevent having to do renovations years after construction is complete because new neighbors just moved in. Next time you’re relaxing on the couch or eating lunch at work, take a minute to try and pinpoint some noise that you may or may not be able to hear!

Share this Post